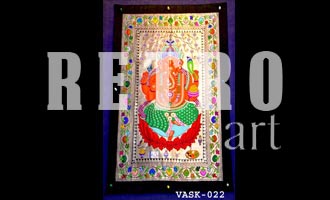

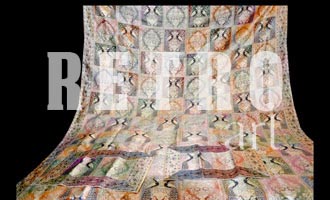

SILK

The origin of the art of weaving in India is shrouded in the mists of antiquity. silk has a long history in India, where it is considered a symbol of royalty and prestige, a "pure fabric" used for all religious, ritual and ceremonial occasions. The first Indian silk, spun as early as 1725 B.C., was produced not by the domesticated Bombyx mori silkworm, fed on mulberry leaves, but from the cocoons of indigenous Tussah, Eri and Muga moths.

Fragments of woven cotton and bone needles have been discovered at Mohen-jo-daro and Harappa, the ancient seats of the Indus Valley Civilization. Even the Rigveda and the epics of the Mahabharata and the Ramayana dwell upon the craft of weaving at length. These weavers of the past were true masters of their craft. Such was their capability that legend even refers to the fabulous semi-transparent saree (a great technical feat) worn by Amrapali, the famous courtesan.

Its legendary cotton muslin was said to be so fine that even oil could not penetrate its finely woven texture. This muslin was rightly called King's Muslin and legend has it that Buddha's body was wrapped in it when he died. Benaras was known for the Jamdani inlay technique where fine patterns were woven all over the body of the fabric along with the weft, in the same count, a technique indigenous to India. Ancient records speak about five tones of white being used - ivory white, jasmine white, white of the August moon, white of rain-spent August clouds and conch white.

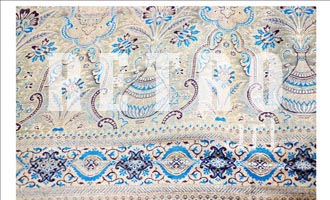

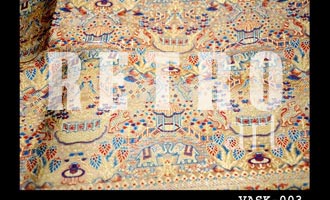

During the Mughal era, Benarasi silk sarees became very popular - Persian motifs and Indian designs studded with gold and silver became the darling of Mughal society. Today they enjoy the same public adulation and are exported across the globe.

These silk products are the result of hours of hardwork. When you buy it from a shop, you cannot imagine how long the whole process of making is. Well, you will know from the price.

A silk thread is used to weave and make patterns on the silk. These threads can be of gold, silver or silk. The price of these products varies according to its thread work and how intricate a pattern is woven on it. This fabric is stronger and more durable than most of the other materials.

To really know the worth of these products, you must know how it is made. You might never have looked at Taj Mahal with such amazement if you didn't know that it is made of all marbel, inside out. "How?" is after all a big question.

How silk is obtained?

Silk is obtained from the cocoons of silk worms. The thread which the silk worm uses to cover itself while in a dormant state is called silk. This thread is taken out from the cocoon of the silk worm when it is in metamorphosis. The cocoon should first be soaked in water for sometime before taking out silk thread from it. The bad news is that the silk worm dies in the process, and the good news is that it contributes to making such a magnificient cloth.

Next, the silk thread is spun and dyed in the desired colors. Now the silk is woven and spun on a loom. Lastly, the silk thread is weaved into the cloth. Now the silk cloth is ready. It is then cut and sewn into garments.

All these processes take a long long time. It is a complicated process too. Everything has to be just right. If you think of it, whatever big bucks they ask for the silk products are really deserved.

Now look at your silk products with new eyes.

Identifying Silk

The burn test is the best way to be sure. Burning silk will leave a powdery ash and will extinguish itself when the flame is removed, just like wool. The easy way to tell silk and wool apart in the burn test is the smell. Where wool will have the smell of burning hair, the silk will have a much more disagreeable smell.